Advantages

DOE-driven formulation development, SPC process control, and application-side validation ensure stable delivery from prototyping to mass production.

Material matrix: PA6/PA66, PP, PVDC, and functional matrices.

High-performance polymer development and manufacturing, serving automotive, packaging, E&E, healthcare, films and fibers.

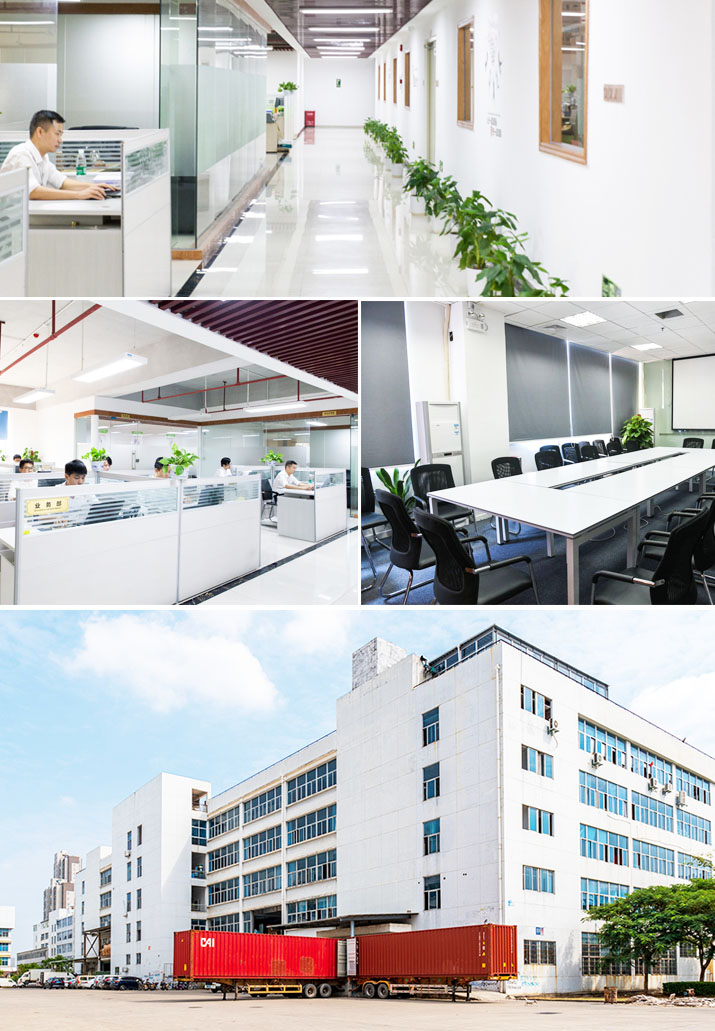

Shanghai Juzhi Plastic Technology Co., Ltd. (“Juzhi Plastic”) was established in December 2010 with a registered capital of RMB 10 million. Headquartered in Shanghai, China’s economic and financial center, the company has focused since its founding on technology development and product manufacturing in the field of plastic chemicals, and is committed to the innovation and application of high-performance materials.

Juzhi Plastic continually strengthens its R&D capabilities, providing customers with end-to-end technical support from material selection and process optimization to product application. Leveraging its deep expertise in plastic chemicals, the company’s products are widely used across key industries and sectors, including PPR pipes, household appliances, daily necessities, automotive parts, packaging, construction, healthcare, films, fibers, pharmaceutical packaging, dairy packaging, and more.

With a strong emphasis on material quality and technical standards, the company has established long-term, stable partnerships with many well-known enterprises, including Mengniu Group, Yili Group, Amcor Packaging (Shanghai) Co., Ltd., and Celanese (Nanjing) Chemical Co., Ltd., ensuring superior performance and broad applicability of its products.

Upholding the principles of fairness, rationality, and win-win cooperation, the company provides customers with high-quality and flexible technical services and support. Driven by innovation and quality, Juzhi Plastic is committed to building stable, diverse, and comprehensive partnerships with customers to jointly advance industrial progress and market development.

DOE-driven formulation development, SPC process control, and application-side validation ensure stable delivery from prototyping to mass production.

Material matrix: PA6/PA66, PP, PVDC, and functional matrices.

Years of experience

Long-term customers

Core patents/processes

Application sectors

Builds a “structure–process–performance” model from molecules to applications, using DOE/FMEA and rapid iteration to shorten formulation cycles, verify results, and ensure reproducibility across projects.

Integrates end-to-end digital scheduling with SPC online quality control, enabling full batch traceability while keeping PPM within targets and ensuring reliable, on-time delivery (OTD).

Works with upstream suppliers and downstream brands to co-develop solutions, achieving agile scale-up from prototyping to mass production with optimized performance, cost, and sustainability.

Tell us your application targets—we’ll tailor a formulation and process window.